Hydraulic fracturing is the initiation and propagation of a fracture by means of fluid pressurization. Hydraulic fracturing has grown in popularity over the past couple of decades in response to increasing public demand for energy alternatives, the discovery of large oil and gas reservoirs in North America and the growing demand for minerals.

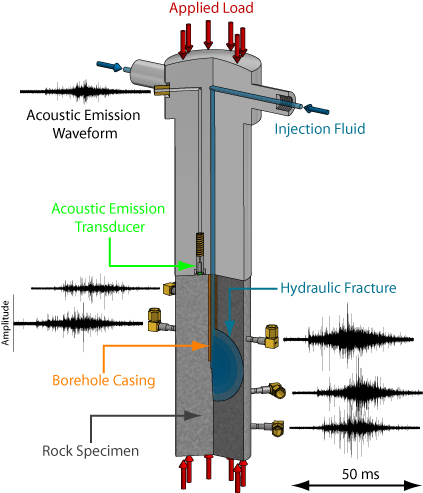

The objective of this research is to conduct laboratory scale hydraulic fracturing experiments, which investigate various hydraulic fracture parameters such as, fluid injection rate, fluid viscosity, stress ratio and rock microfabric. We use deformation measurements, ultrasonic velocity surveys, acoustic emission monitoring, micro computed tomography imaging and thin section analysis to study the micromechanics of hydraulic fracture initiation and propagation and quantify induced fracture geometry.

Hydraulic fracture experiments are conducted in a triaxial geophysical imaging cell (ErgoTech). Fluid is injected through a central borehole which can be sealed up to approximately 70 MPa by a multi-O-ring packer system (Designed by Laszlo Lombos). Acoustic Emission is monitored continuously by 18 piezoelectric sensors in direct contact with the rock specimen. Fluid is inject at constant flowrates up to 7.5 mL/min using a servo-controlled hydraulic pump capable of delivering a maximum pressure of 100 MPa.

Related Publications

-

Goodfellow, S.D., M.H.B. Nasseri, and R.P. Young, The influence of injection rate on Hydraulic Fracturing of Westerly granite, ARMA Conference, June 23 – 26, 2013, San Francisco, California, USA.