During the Fall Break CivMin grad students undertook a

Structural Engineering Field Trip to Atlas Tube and the Gordie Howe International Bridge

CivMin graduate students, led by Professor Jeffrey Packer, undertook a structural engineering-themed field trip November 1-2. The two-day trip led them to Atlas Tube in Harrow, Ont. and to the new cross-border bridge construction site connecting Windsor and Detroit. Support of this trip with 34 participants mostly made up of MEng, and some MASC and PhD students, was provided with the generous backing of Atlas Steel, with the company providing a motor coach, hotel accommodations and a welcome lunch.

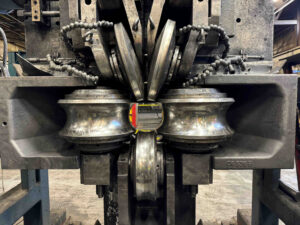

The highlight of the trip was a visit to Atlas Tube, a division of Zekelman Industries. Founded by the late Harry Zekelman, Atlas Tube is the leading manufacturer of hollow structural section (HSS), straight-seam electric-resistance welded (ERW) pipe piles and specialty tube in North America. The company rolls more than 1.2 million tons a year at seven facilities across North America. Additionally, the introduction of “Quick Change” technology to minimize cycle times has led to delivery times of just two to four weeks, the shortest in the industry.Packer sums up the enormous facility, “We went through the Atlas Tube steel manufacturing plant, where they basically bring in hot rolled steel coils, then they unravel it, and pull it as it goes through machines as a strip. It’s then bent up into a circle and welded into a circular tube. Then, if you want a square, rectangular tube, then it’s squashed into a square, doing it cold and pressing it into shape. Adding, “We went through the whole production facility. There was one line that was running, so we could observe the process, then go through their warehouse where they’ve got thousands of tons of their product stacked. They have up to 70 or 80 trucks a day leaving just from the Harrow plant. It is astounding how much they’re shipping out each day.”

Recapping the company’s business, as it relates to the structural engineering side of buildings, Packer offers, “They sell a lot of steel columns and bracings, for low-rise construction. If you go to a big box store like Costco, Walmart, and Loblaws, you see these eight-inch square columns go up to the very high ceilings. All these columns are hollow structural sections, generally from Atlas Tube as well.”

Further impressing the vastness of the operation, Packer offers, “The company, has about 50% of all structural tubing sales in North America.”

While in the area, Prof. Packer knew one of the largest bridge projects in North America, the Gordie Howe International Bridge connecting Windsor and Detroit, would be a worthwhile visit. The difficulty, however, is that non-workers are not allowed on the construction site, so the group was left to see the operation from a viewing platform. Packer recalls, “When we got there, the Director of Marketing and Communications turned up, and she gave an excellent summary for about half an hour. They’ve also promised to give us a full technical seminar in due course, run by one of their bridge designers and bridge contractors. I think we’ll do that during the bridge engineering graduate class next semester, given by Paul Gauvreau.”

“It’s quite a sight as it’s the longest span cable-stayed bridge in North America, with a span of over 800 metres,” Packer relays.

The initiative for the trip came from wanting to provide some real-world perspective to large projects. Packer says, “Through a connection with Brad Fletcher and Atlas Tube, CivMin is receiving a donation of over $100,000 worth of tubular steel for our new AMD (adjustable multidimensional) machine in the STF (Structural Testing Facilities). They’re supplying the tubular posts of the new testing machine, so they’ve been kind to us in that respect. So there’s a very good connection with Atlas Tube and this led to our invitation there.”

Summing up the hospitality shown, Packer recounts, “I’ve known Fletcher for 20 years. He’s their technical specialist based in Chicago, now their commercial headquarters, and he flew up especially just to meet with the class and talk to everybody. What a treat.”

By Phill Snel