A donation from industry to CivMin has allowed for the acquisition of specialized machinery used in preparing rock samples for testing.

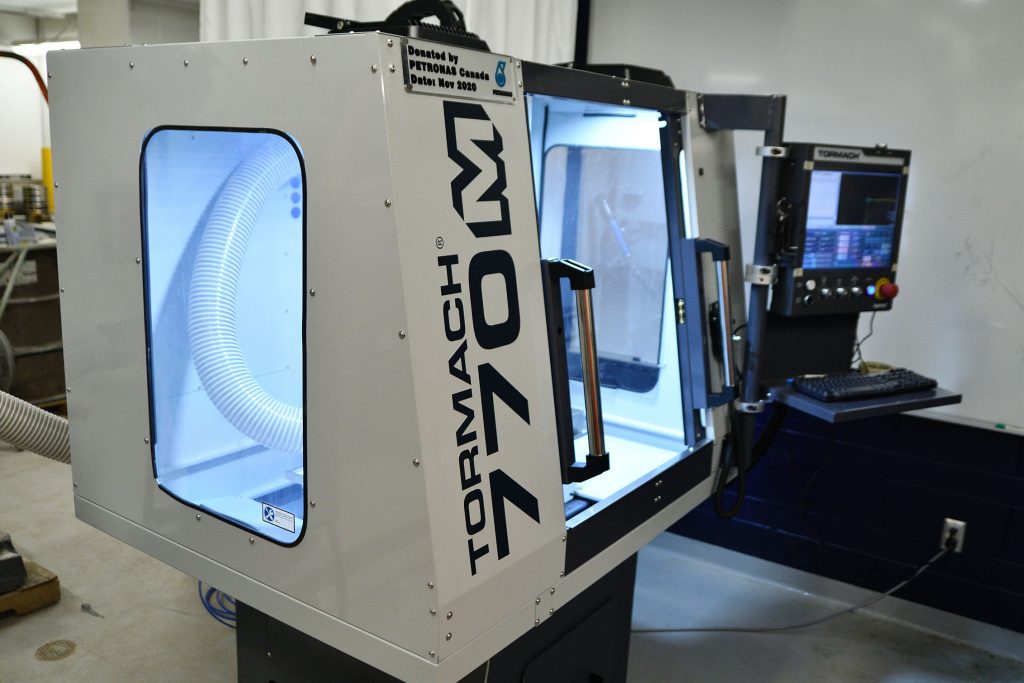

PETRONAS Canada’s donation of $25,000 to Grasselli’s Geomechanics Group, led by Prof. Giovanni Grasselli, has resulted in the purchase of a new computer numerical control (CNC) mill. The CNC mill is used to precisely prepare rock samples in the Concrete and Materials Preparation Lab in the Galbraith Building.

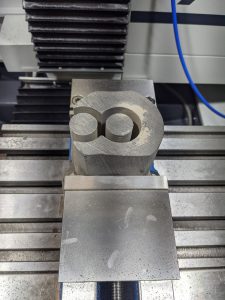

Previous attempts at preparing rock samples with Claraia fossils with existing equipment were fraught with frustration and disappointment, when some 240 attempts to prepare samples were met with no success. Now, after the November 2020 donation for the new equipment, a 45-minute milling process results in ideal testing specimens.

The computerized manufacturing process, in which pre-programmed software and code controls the movement of the production equipment, allows the delicate layered rock to be prepared without the use of the usual cooling liquids. Instead of using water during coring, which can make the rock unstable and fragile, the gentle and dry process results in competent samples. Typically, rock is prepared into cylindrical samples to be tested for its physical properties such as strength and stiffness which are ultimately used in engineering design and numerical modelling.

Grasselli explains, “The rock formation [Montney] is known to swell when exposed to fresh water and to exhibit weak structural laminations. The water sensitivity and fragility of the material makes it very difficult, if not impossible, to prepare testable samples using conventional sub-coring methods which requires the use of water.”

Measuring mechanical properties of the rock formation at depth for engineering purposes is crucial. With intact specimens now readily available, testing is accomplished by recreating stress conditions from one kilometre to two kilometres below the surface. These stress conditions are known to impact the behaviour and response of the rock. The ability to have intact samples will push this research and will help Canada in its goal to reduce GHG emissions, as we can better use our underground resources, such as geothermal, natural gas and carbon sequestration.

“In our current research, we are investigating industry problems related to wellbore stability, microseismicity, nuclear waste storage, and hydraulic fracturing design,” he adds. “A proper undertaking of the characterization of the material will better inform our numerical models and help our industry partners improve the social, economic, and environmental impacts of their operation.”

Benefits of the new equipment extend beyond Grasselli’s Geomechanics Group, with its 25 faculty, staff and research students. Others at U of T, from Physics and Earth Sciences, use the lab’s machinery to prepare samples for a broad array of research as well. “We expect this equipment to be of continuous use to U of T for at least the next 20 years,” predicts Grasselli.

Acknowledging others, Grasselli offers, “I want to really offer a big thanks to those we had tremendous help from. The leadership of Matthew Adams [Interim Director at Unconventional Center of Excellence (UCOE)] and Nicole Deyell [VP Development at PETRONAS Canada], were instrumental in getting this donation. Without them, this wouldn’t have been possible.”

By Phill Snel