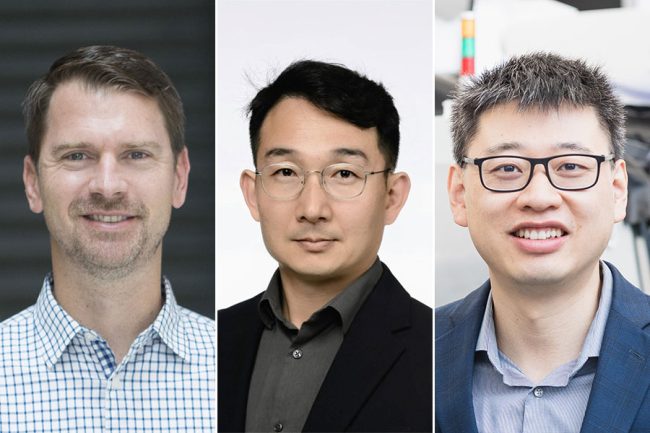

CivMin Professor Oh-Sung Kwon is among three professors who recently received grants to study various aspects of this emerging technology

Small modular reactors (SMRs) represent a new paradigm that could change how and where nuclear power is used to meet our energy needs — and U of T Engineering research could help point the way forward.

Professors Greg Jamieson (MIE), Oh-Sung Kwon (CivMin) and Yu Zou (MSE), recently received funding from the NSERC-CNSC Small Modular Reactors Research Grant Initiative. Over the next three years, each of them will be leading a project that seeks to improve the design of SMR technology, from the materials used in their manufacture to the ways in which they are operated.

“Canada has a long history in the nuclear space, and a lot of experience building and operating nuclear power plants,” says Jamieson.

“So far, these have all been large facilities designed to meet the needs of major population centres. But we also have many communities and natural resources that are located hundreds or thousands of kilometres away from these big cities. With a geography like that, SMRs start to make a lot of sense.”

While there are currently no SMRs in commercial operation, several companies and organizations around the world are working on pilot facilities to demonstrate proof-of-concept. For example, Ontario Power Generation has begun site preparation activities for an SMR project at its existing Darlington site in the Greater Toronto Area.

These plants would be small — producing less than 300 megawatts of power, as compared to two or three times that amount from Canada’s existing plants — and built with pre-fabricated components that could be shipped to remote locations and assembled on site.

Since they operate without producing any greenhouse gas emissions, SMRs are seen as a potentially cleaner replacement for the diesel generators that are currently the industrial standard in remote locations. And electricity isn’t all they produce.

“Like all nuclear plants, SMRs generate heat, which produces the steam that is used to run the turbines,” says Jamieson.

“But you could also use this heat in other ways: for example, district heating, or for industrial processes such as hydrogen generation or the early stages of oil sands processing. There are a lot of possibilities.”

As a human factors researcher, Jamieson will be focusing on how the plant’s operators will monitor and control the technology. His project builds on some of his previous experience with the nuclear industry, but also represents a contrast to current industry standards.

“Large nuclear plants have operating procedures oriented around a single crew of operators monitoring a single reactor,” says Jamieson.

“But small modular designs open up new possibilities, such as a single crew monitoring multiple reactors, which raises questions about how you distribute human attention.”

Many proposed SMR systems also include what is known as ‘inherently safe design.’ This means that systems are designed to passively shut down if operating conditions deviate from normal.

“Inherently safe design is a good idea, but we want to understand if there are situations where operators, possibly as a result of misinterpreting data, might mistakenly override those systems,” says Jamieson.

“This is something that was a factor in previous nuclear accidents, such as at the Three Mile Island facility in the U.S.”

In addition to differences in their potential modes of operation, SMRs might also require the use of different materials than current reactors, ones that can stand up to harsher working environments. This aspect is the focus of Zou’s research project.

“In today’s reactors, water is usually used as the cooling fluid,” says Zou.

“But many SMR designs use molten salts as the coolant, which can be more corrosive than water. Other designs use water, but they operate at much higher temperatures and pressures than traditional reactors. This means that the pipes, heat exchangers and other components need to be able to stand up to much harsher conditions.”

Zou and his team are working with collaborators at Natural Resources Canada and Dalhousie University to study how various materials might react to these tougher conditions. These might include nickel or iron-based alloys in common use today, but they will also consider new materials, such as high-entropy alloys, that haven’t been used for these applications before.

Components for SMRs could be made via additive manufacturing, also known as 3D printing. This method, which Zou’s team has expertise in, can significantly reduce the time from the development to the production.

The team will conduct physical experiments in the lab to test the mechanical properties of these materials, then feed the results into a set of computer simulations. Those simulations, in turn, will inform the development of future lab experiments in an iterative approach.

“Our goal is to build up a database that could be consulted by the designers of future SMRs,” says Zou. “It would also help regulators, as the lack of data about material behaviour under the relevant conditions makes it hard to assess safety.”

For their part, Kwon and his team are looking at how SMRs might react to seismic activity.

“Seismic analysis involves looking at how vibrations caused by seismic waves will affect a structure, including whether or not there are resonances that would amplify the effects of these vibrations,” says Kwon.

“In the case of a nuclear plant, we are interested not only in how vibrations might affect the building itself, but also the equipment within the building.”

One of the factors that Kwon and his team are focusing on is the properties of the soil underneath the reactor and containment buildings.

“Today’s plants undergo a lengthy site selection process that ensures they are seated on stiff, compacted soil that will not liquify in the case of a seismic event,” he says.

“But SMRs are designed to be shipped to remote locations, where there is less choice about where to situate them, so they may have to be designed to work on softer soils. In Canada’s North in particular, they might be seated on permafrost. If climate change causes that permafrost to melt, it could affect the seismic resilience of the facility.”

While SMRs are still a long way from widespread application, research from projects such as these can inform their development and keep Canada at the forefront of innovation in this dynamic sector.

By Tyler Irving

This story originally published by Engineering News