Lassonde Mineral Engineering students hold the first in-person fall Capstone presentations in three years.

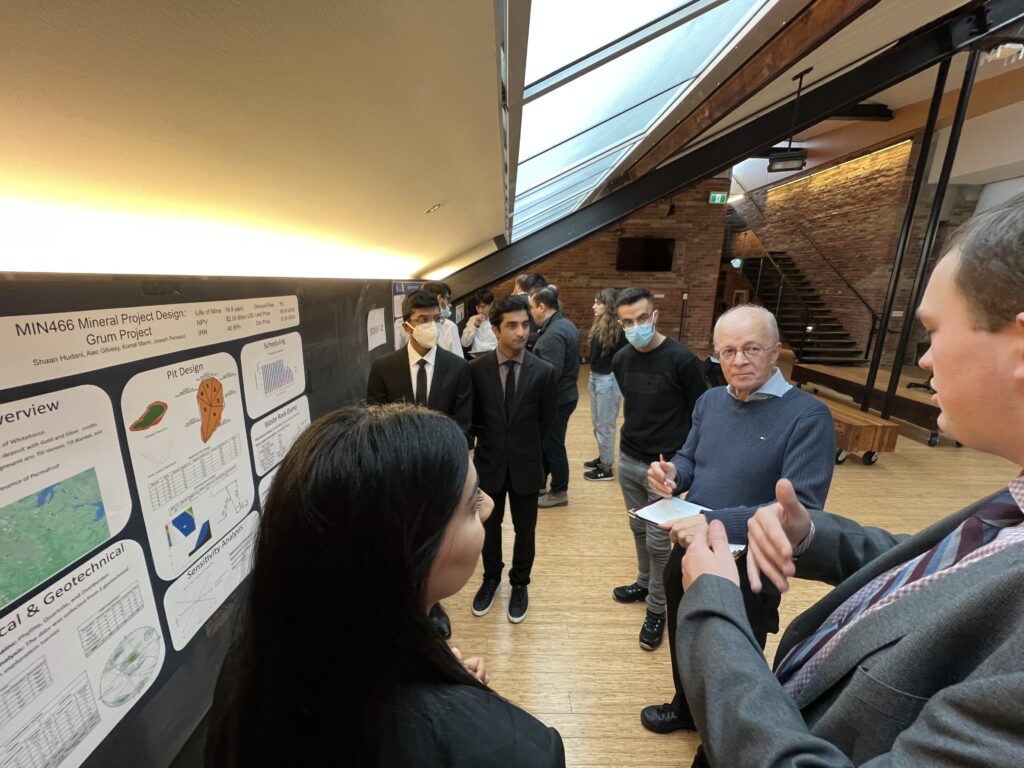

Fourth-year Min students recently held their fall Capstone presentations, the first in-person fall event in three years.

The annual rite of passage involves completing a group project to solve a mine design challenge, of a formerly active mine in the Yukon, with environmental legacy issues. The results must be summarized in an engineering design report and an in-person oral presentation with a display, in the form of a poster. “The main goal is to give the students the challenge to see if they can apply all the skills and knowledge they have learned in the previous three years of courses, in a real life scenario,” says Prof. Kamran Esmaeili.

As with many academic quandaries, explains Esmaeili, “There is no right or wrong answer – it’s an open-ended question. You could accomplish a successful design in multiple different ways, but which one is the optimum design from both safety and project economics perspectives?”

The exercise is structured to simulate not only real-world technical issues, but also, “learning about working together as a team, accomplishing the tasks together, dividing up the tasks among among themselves. And they also learn to use lots of their communication skills – interpersonal communications, writing communication skills and presentation communication skills. These are other important outcomes of this particular course.”

Of the ten presenting students, many have participated in the Professional Experience Year Co-op Program, known as PEY Co-op. Asked if he thinks there’s a difference in approach to the assignment for those who do, or don’t, pursue a PEY, Esmaeili says, “I think so. I think it makes a significant difference in the way that you look at a mining design project, because you understand the limitations and restrictions of a real-world mine operation. Also, it can give you a better understanding of the challenges and the potentials to improve a mine operation. So, yes, certainly it has a significant influence on how you look at the whole project.”

Overseen by industry judges Brian Buss, P.Eng. and Larry Smith (CivE 7T2), along with Prof. Esmaeili, the three teams were subjected to rigorous questioning to justify their recommendations. Smith has been involved in this Capstone project for many years, and is a well-known expert in mining finance, mineral economics, as well as giving detailed lectures on cash flow analysis, cost estimation, commodity price forecasting and beyond. First-time guest judge, Buss, is a well-known expert in mine planning and design.

At times the questions could be philosophical in nature, asking if a given legacy environmental issue is an opportunity or a liability. Sometimes the answer is “both” as there is opportunity to use new methods to minimize environmental and social impacts, but there can be retained resistance in a community due to what has happened historically. “If we do the same mine today, how these problems could be avoided is something an opportunity for them to learn from. Learn from what happened in the past and propose something that could minimize these impacts,” says Esmaeili. Further adding, “In the winter term, in the second Capstone, they look at the environmental and social impacts of the mining project. And now that they are aware of these environmental problems, they should think about what can be done differently to avoid or minimize the environmental impacts.”

After the Capstone presentations were completed, the close-knit cohort of assembled students, professor, TAs and industry professionals sat down for a well-deserved family-style lunch together in the atrium on the fourth floor of the Lassonde Mining Building.

By Phill Snel

Capstone posters

Poster by Team 1: Shaan Hudani, Alec Gilvesy, Komal Mann, Joseph Persaud

Poster by Team 2: Raphael Beekmeyer, Kyle Wong, Shi Kai Li

Poster by Team 3: Andriy Kalatskyy, Michael McCulloch, Shivan Singh

Summary of the project assigned:

The information on a polymetallic (lead-zinc-gold-silver) ore deposit located in Yukon, Canada, has been provided in the form of a block model (ore grades, rock types, etc.). In addition, some geotechnical information (geotechnical borehole logging data, geotechnical laboratory data) for the main rock units encountered in the area of the project has been given. You should perform a conceptual/pre-feasibility study of developing an open pit mine for the ore deposit. The following components will be analyzed in detail for the project:

- Geotechnical rock mass characterization and classification

- Pit slope stability analysis

- Pit design and optimization

- Long-term production planning

- Waste rock dump design

The results must be summarized in an engineering design report and an oral presentation (in the form of a poster).